|

|||||||||||

|

|

|||||||||||

|

So you want to build a lathe? Lots of people have tried and its certainly possible though not easy. Lathes are essentially simple bits of equipment but decent ones are expensive and heavy. A quick search of the web will find many pages covering various home built lathes - not least because the process of actually building a lathe is probably as much fun as using the final item. Probably the most ‘famous’ route in lathe building is the follow the exploits of David Gingery in his famous set of books. If you are interested the book the read is: The Metal Lathe: 2 (Build Your Own Metal Working Shop from Scrap) However there are simpler and easier options like this Afghan lathe and plenty of middle ground. I haven’t built a lathe yet - but as my original metal working lathe leaves something to be desired and my new Wizard lathes are very small, I’m still tempted. Whilst you can build one completely from scratch it helps to get lucky and find some suitable bits. The following is a Black & Decker drill and Black & Decker horizontal drill stand I picked up from 2 different stalls at a recent car boot sale:

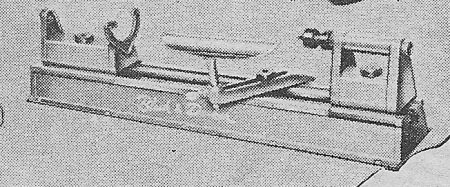

Its very noisy (as electric drills usually are) and only has 1 speed - but complete with its existing 1/4” chuck its pretty much a lathe headstock. My initial thoughts were to build a crude metal working lathe with it - but I think its more suitable for a wood turning one instead. The picture below shows its not a new idea. This 1957 Black & Decker advert from the Hobbies catalogue of the same year shows a very similar drill stand being used as a headstock on a wood turning lathe.

This next photo was very kindly donated by Rosermary Calazel and shows this type of kit complete with accessories and drill.

Drill based lathes like this are still available new today.

Actually drill chucks are a good option even if you build your own headstock spindle. I’ve managed to find several at give away prices:

Of course a proper 3 or 4 jaw lathe chuck is better if you can find one. Most are either too big or too expensive for me - but I picked up this lovely 2.5”(ish) Cushman chuck at a car boot sale. Its heavy and is probably an antique but if I ever mount it up I suspect it will work just fine.

For a home made headstock a pulley is useful too. This one is a single pulley - but a multistep cone pulley is better if you can find one. I have used a single aluminium pulley like this in the rebuild of my original lathe headstock.

With a bit of luck you might find some actual lathe components. Below is a rather large TULL International belt driven headstock from a wood turning lathe. Made in 1989 but only cost me £8 - I don’t know if the motor works - but its sure to have some useful parts anyway!

Below are a couple of wood turning faceplates and a tool rest. All picked up for pennies at a local car boot sale. On one of the faceplates you can see the wooden block onto which was glued a part made bowl in order to allow its inside to be turned.

Some interesting links:

|

|

All text and images Copyright © 2000-2011 Roland Givan, unless otherwise stated. All Rights Reserved. Game artwork copyright their respective publishers. |

|

[Home Page] [Old Lathe Project] [Wizard lathe] [Build a lathe?] [Lathe Gallery] |